As one of the longest-standing names in photopolymer plate production, primarily for the packaging industry, KB Polymers has evolved into more than a high-quality plate supplier. ‘Our team’s design, artwork creation and origination expertise, in conjunction with DuPont Cyrel’s cutting edge software and production technology, add value to brand owners and their converters,’ maintains KB Group operations manager, Ricky Maconi. ‘Our sales consultants have the knowledge and technical backup support to solve customers’ most challenging origination and production issues. Many of our dedicated and well-trained staff complement, who started their careers with Kiley Baker 20 to 30 years ago, have continuously honed their technical skills to stay up to date with technological advances.’

Operating as a one-stop shop under one group umbrella motivated management to invest in platemaking capabilities two years ago because alongside in-house repro expertise, platemaking has the greatest influence on the quality of labels produced by the KB Labels division. Ricky cites this as a prime example of prioritising collaboration and utilising the group’s combined skills to enhance KB Labels’ proven track record as a service-oriented supplier to blue-chip FMCG brands in the food, beverage and pharmaceutical sectors. ‘These brand owners recognise and value our attention to detail and production excellence,’ he states.

MD Rew Wannenburg reports that although there have been many challenges through the years, the Covid-19 pandemic has tested the resilience of the group’s team as well as that of its customers and suppliers. ‘It has forced everyone to think outside the box, making innovation and diversification a necessity not only to survive but to thrive during this challenging time. Many companies, such as DuPont Cyrel and Rotocon, have formed new business partnerships (PPM Festive 2020). We trust that our relationship with them as a platemaking equipment and consumables manufacturer and local distributor will grow from strength to strength.’

Ricky adds that throughout many decades as a supplier to KB Polymers, DuPont Cyrel has proven to be a reliable business partner. ‘The company has always offered superior quality products and consistently concentrated on pushing the boundaries of next-level plate technologies.’

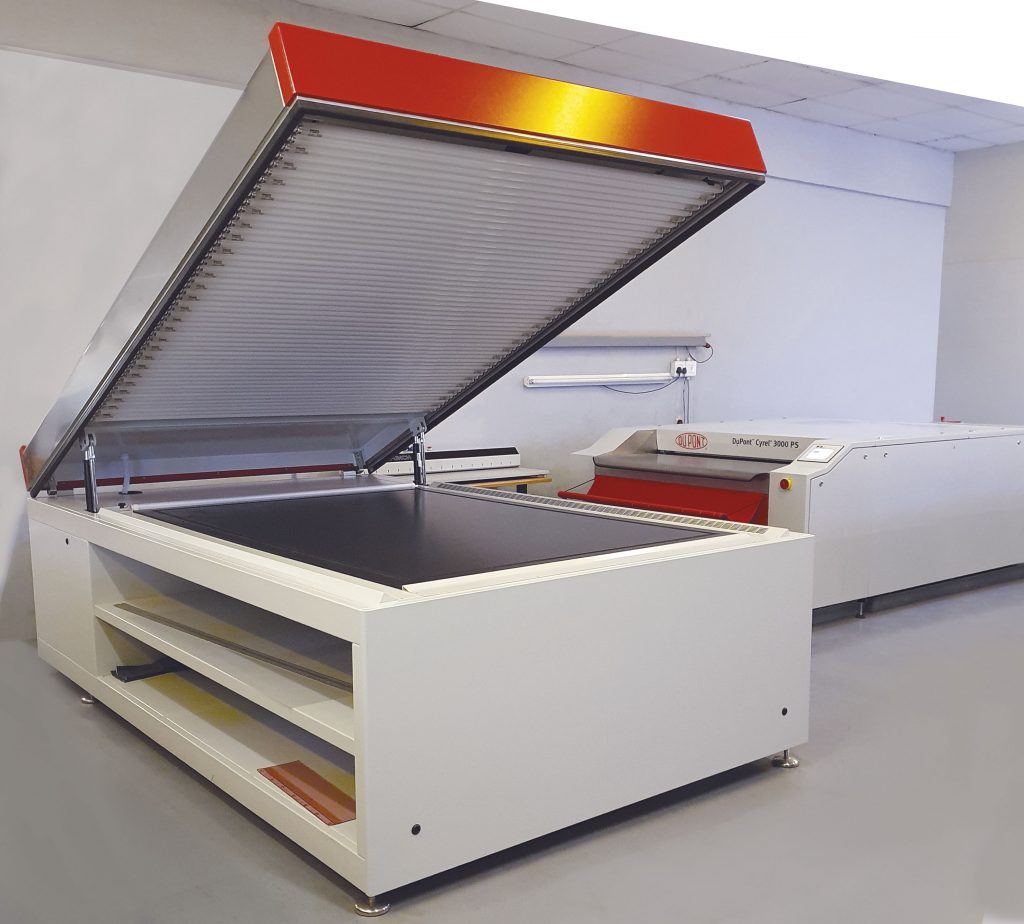

In April 2019, to realise the vision of streamlining its Johannesburg flexo platemaking facility’s capabilities and cost efficiencies by increasing daily production output, bringing down overtime and shift rates, and reducing environmental impacts, KB Polymers invested in a DuPont Cyrel Evo 3000 exposure unit, 3000 PS solvent processor and 3000 LF light finisher. This equipment complemented a 2018 investment in a DuPont Cyrel 2000 D six-drawer plate dryer.

Rew stresses that the group’s objective has always been to help customers build their brands and consistently provide products and services that enhance customer satisfaction.

‘‘We value customer loyalty, therefore, quality and service excellence, are and always will be our primary focus. However, we realise that we wouldn’t be able to achieve high levels of customer satisfaction without a solid supply chain,’ he comments. ‘Rotocon has been a supplier of flexible/rotary dies and magnetic print cylinders to KB Labels for around 10 years. The team’s technical expertise and professionalism have helped us to maintain our standard of excellence. Now KB Polymers looks forward to building on this partnership as Rotocon technically supports the DuPont Cyrel equipment and supplies the photopolymer materials.’

Rotocon director Patrick Aengenvoort explains that in addition to a dedicated technician to maintain and service the equipment, he is working closely with the production team on forecasts to ensure that the right type of stock is always readily available.

Click here to read this article in the e-mag.