The packaging industry is moving forward with efforts to reduce its impact on the environment. Renewable and recyclable packaging already has an advantage in meeting sustainability targets compared to other packaging solutions.

‘Consumers expect liquid paperboard (LPB) packaging that’s not only easy on the environment but also safe and innovative by design. The LPB industry will have to meet the needs of the future to remain competitive,’ comments Raymond Dube, MD at Nampak Liquid Cartons.

According to Raymond, it comes down to two factors: sustainability and embracing the power of technology. ‘Nampak’s LPB gable top cartons are made from virgin wood fibres, which come from responsibly managed forests. This means trees are grown for the paper and paper packaging industry to provide environmental, social and economic benefits in line with sustainable development. As a renewable resource, for every tree felled, a tree is planted in its place,’ he explains.

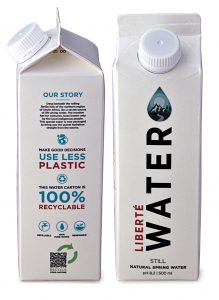

In addition, he adds that the carbon is also ‘trapped’ inside the cartons, so it isn’t released into the atmosphere. ‘A study found that an LPB carton made from sustainably-sourced wood has a 47% lower carbon footprint than virgin PET bottles and a 37% lower carbon footprint than recycled PET bottles. Nampak’s 500ml gable top cartons contain 70% less plastic than a PET bottle of the same size, and are 100% recyclable,’ Raymond comments.

The potential of RFID tags, microchips that emit a radio signal to track and trace goods, is impressive for application to FMCG product packaging.”

Once recycled, liquid carton paper can be made into everything from kitchen towelling to takeaway coffee cup holders. These items can be recycled up to six more times, while the carton’s polyalu layers can be separated and transformed into items like pallets and roof tiles.

‘We are also seeing other innovative solutions that may change the paperboard packaging game for environmental good. For example, our supplier Elopak has developed packaging that offsets emissions created from the carton’s manufacturing and distribution processes,’ Raymond reports.

It’s a matter of time before radio frequency identification (RFID) tags and blockchain technology will gain mainstream traction. With more consumers buying in bulk and the cost of living increasing, there’s pressure on manufacturers – particularly those in the FMCG industry – to create packaging that keeps food safe and extends shelf-life. Consumers also want to know exactly where products come from as there’s growing support for ethical brands.

Smart packaging can tell consumers if a product has been tampered with, exposed to a higher temperature, its estimated shelf-life, and exactly where the ingredients originate.

Tiny RFID tags are microchips that emit a radio signal to track and trace goods. ‘They’re still mostly used for high-end products, but their potential to go beyond what barcodes can do is impressive, as they can also store data such as temperature and nutritional information,’ he explains.

Another promising technology is the QR code, which can deliver a personalised digital consumer experience through a simple scan, from tracing the product’s lifecycle to supporting the circular economy. ‘For example, QR codes on the gable top cartons of Liberte Water direct consumers to the Fibre Circle website where they can learn about how and where to recycle the packaging.’

‘LPB has been designed to provide taste and odour neutrality, and the tamper-evident closures on Nampak’s gable top cartons guarantee the product is safe. When combined with the technologies mentioned, the future possibilities of where LPB can go are endless,’ concludes Raymond.

Click here to read this article in the E-mag.