With South Africa’s relentless energy crisis and high cost of supplemental power to mitigate load-shedding, energy consumption remains top of mind for Print Service Providers (PSPs) across the country. Against a backdrop of power cuts and rolling black-outs, packaging and print manufacturers are forced to seek solutions that maximise productivity and efficiency, making it more essential than ever to invest in technology that can make the most of the time when the lights are actually on.

Furthermore, short runs, short time to market and multiple SKU demands aren’t just on the rise locally, but is gaining exponential traction globally. What’s required is highly-productive digital printing and finishing equipment that requires optimal usage and minimal personnel, capable of reducing raw material wastage with the highest precision and accuracy. Fortunately, Midcomp has the solution!

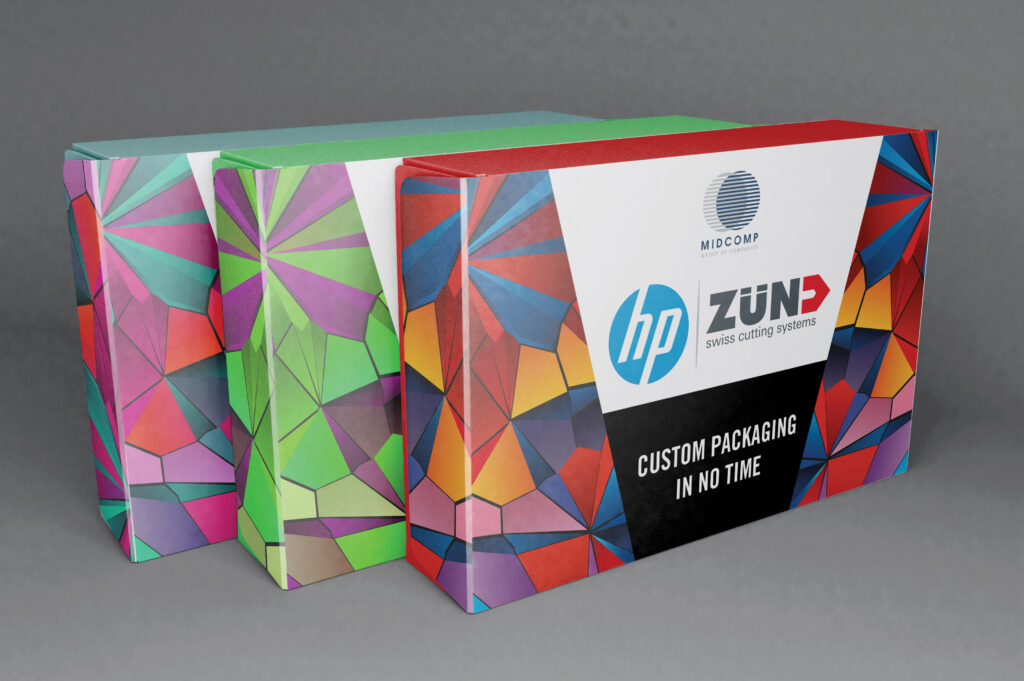

Whether it’s the HP Latex R-Series Hybrid flatbed printer, the HP PageWide XL Pro Series or the Zünd Q-Line cutting system, Midcomp has a solution to address any and all productivity and efficiency challenges.

Beside mitigating the energy crisis, PSPs need to stay future fit and abreast with current trends in the print and packaging sector. According to Midcomp’s Group Marketing Director Angelique Greer, having a large format Zünd Swiss cutting system with a HP Latex R-Series Hybrid flatbed printer in your arsenal for instance, will give you the competitive edge required to set your business apart from the rest.

‘Both machines are perfectly integrated and allows PSPs to maximise productivity, especially with load-shedding becoming widespread, as well as meet the demand for bespoke, short-run packaging,’ comments Angelique.

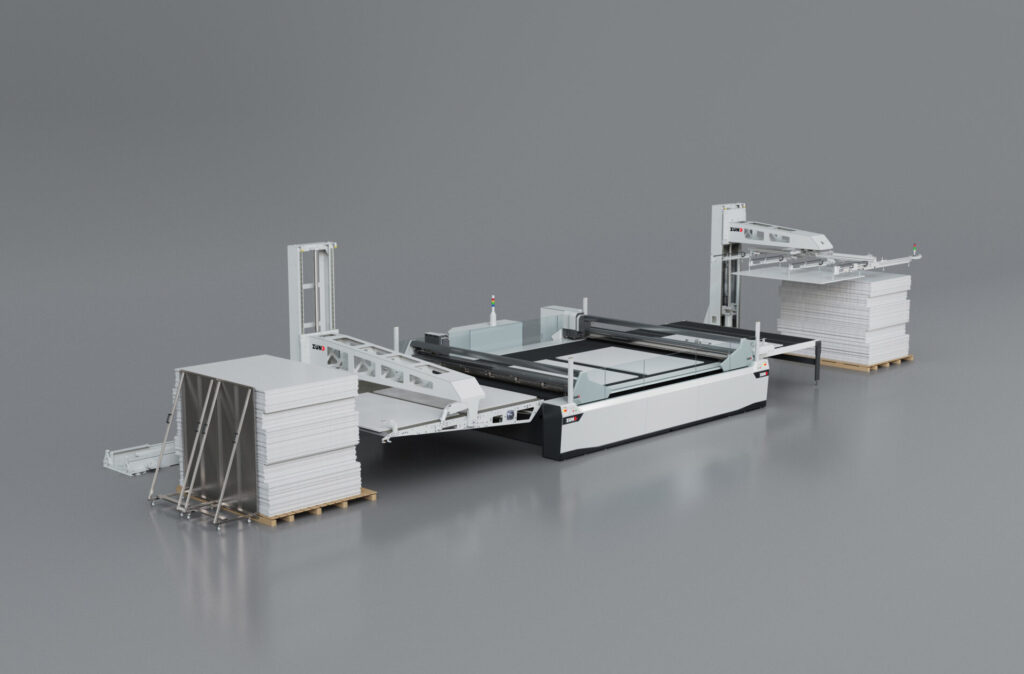

Zünd Q-Line: Swiss precision

Angelique speaks fervently about the brand-new Zünd Q-Line large format digital cutter. ‘It’s part of a series of cutters that delivers with renowned Swiss precision, reliability and predictability.’ For businesses to survive in the current economic climate, Angelique says agility and versatility are critical, and business owners need to be able to say yes to more and then deliver on time, every time. ‘Fortunately, the Zünd Q-Line is modular and can be configured with autoloading, stacking and an automatic tool changer.’ For example, the Zünd Q-Line can crease and cut cardboard and carbon fibre, route acrylic and aluminium, trim fabric banners, kiss and die cut vinyl, and even trim paper posters. ‘You could produce more per hour without putting additional strain on resources during the available uptime. Sky’s the limit,’ she says. As corrugators and packaging companies around the world continue to invest in high-end digital printing presses, so does the realisation of personalisation in packaging take hold. These companies are adding value to their offerings by enabling very high-volume short run jobs offering variable data and customisation.

‘This puts traditional analogue cutting systems and click presses under the microscope because they cannot cope with frequent variations in design,’ comments Angelique. ‘The Zünd Q-Line is the first cutter of its kind that now begins to match the productivity of high-speed digital presses.’

This range of cutting systems impress with their flexibility. Whether you’re cutting fabric or acrylic, cutting, creasing or perforation, the wide range of materials and processing methods make the cutting solutions almost universally applicable. ‘It helps you better cope with increasing numbers of short runs and customer demand for customisation and personalisation. While it’s focused mainly on the packaging sector, it can do so much more,’ Angelique explains.

Testament to its cutting-edge design, Zünd won the 2023 Red Dot Award for best product design for the Q 32-32 D cutter, the flagship product in the newly-launched Q-Line. The Red Dot Award is an internationally renowned prize for high-quality design.

With a wide modular range of units to choose from, there’s a Zünd cutter to fit any application and requirement, and not to mention, pocket. There are currently five models in the range, including the state-of-the-art Q-Line, the highly-modular G3 cutter, the compact S3 cutter (designed for maximum speed), the industrial-ready D3 cutter and the ergonomic L3 cutter with high-speed punch tools. ‘Zünd’s cutting systems and software combine to form an unbeatable solution that fits seamlessly into your production process, whether you’re looking to automate your cutting, or invest in powerful, future-proof cutting technology,’ comments Angelique.

HP Latex R-Series Hybrid: Success in the short run

Offering a better consumer experience has been a source of significant disruption recently, and if you own a printing business, you might want to consider offering a highly unique product: Latex Printing.

Angelique says pairing a large format Zünd Swiss cutting system with a HP Latex R-Series Hybrid flatbed printer can meet the demands of printing on both rigid substrates like corrugated board, folding cartons, foam board, metals and acrylics, as well as flexible substrates such has paper, vinyl, PVC, leather, fabric and plastic films. ‘Flexible water-based HP Latex inks enable better folding and bending without cracking compared to UV ink-based technologies.’

Latex printing, she explains, works like most printers, and uses print heads to distribute inks. But that’s about where the similarity ends. Latex ink printers use latex as the carrier for colour pigments, and that simple switch brings phenomenal advantages. ‘Latex printing is water and scratch-resistant, and can even withstand a number of chemicals. Vibrant colours and clear graphics can be produced with no additional drying time and don’t need lamination for short-term use.’ Angelique adds that latex printing can also produce an astonishing assortment of products that are less toxic for human beings and features some of the highest of environmentally-friendly accreditations. HP also offers a take-back program so it’s easy to recycle used supplies and materials.

The HP Latex R-Series Hybrid flatbed printer is known for consistent image quality, and delivering crisp, professional results that you and your customers can be proud of.

‘However, it’s the machine’s versatility that really sets it apart,’ Angelique enthuses. The machine can be used with over 500 different substrates. ‘If a customer wants it done, it’s likely that the HP Latex R2000 can get it done. It has the ability to transform rigid and flexible printing in ways you never thought possible.’

For smaller board formats, the HP PageWide XL Pro Series also features end-to-end cut-sheet workflow, which allows users to print two-sided on cut-sheets, as well as HP’s large-format auto sheet feeder and versatile high-capacity stacker. The HP PageWide XL Pro Series uses a variety of types and sizes of paper, cardstock and boards, from A2 up to B1 in size, and can print on rigid stock up to 10mm thick. ‘It’s ability to print large areas of solid colours in approximately three seconds enables converters to produce printed bespoke gift boxes in a day instead of a week,’ says Angelique.

Walk the walk

Angelique says sustainability on a broad scale is vital to fall in line with world trends away from non-sustainable manufacturing processes including waste management.

‘It’s easy to ‘greenwash’ commitment to the environment but without the necessary focus on all elements of the manufacturing process and how each of these processes impacts on the environment, leaves the cycle incomplete,’ says Angelique. ‘Ink technologies that boast warning labels on their ink bottles cannot then be part of a green manufacturing process. With digital printing systems, these warning labels are prevalent but there are green printing solutions available using inks which are water based and contain no VOC’s (Volatile Organic Compounds).’ Fortunately, HP Latex inks falls into this category and, by definition, are suitable for primary food packaging – unlike UV cure and solvent-based inks which are only suitable for secondary food packaging.

Midcomp has a highly skilled team of experts ready to nurture your success and be your catalyst for growth. ‘Being a proudly South African company, we understand the challenges in South Africa and what it will take to build a sustainable, highly profitable business.’

For more info, or to arrange for an onsite/online demo, contact Midcomp on (010) 020 9999; email sales@midcomp.co.za; or visit www.midcomp.co.za

Red Dot award for Zünd

Swiss cutter manufacturer Zünd won the prestigious 2023 Red Dot Award for product design for its Q 32-32 D cutter, the flagship product in the newly launched Q-Line. The new Q-Line generation of cutters is the result of a completely new design concept based on a distinctive style. The precisely dimensioned tools, slightly inclided towards each other, define the shape and create a balance look.